Motors and Instruments applications in UAV

Motors and Instruments applications in UAV

1. Brushed DC Motors in UAVs

-

Limited Use: While historically used in smaller, simpler drones, brushed DC motors have limited applications in modern UAVs due to several drawbacks:

-

Efficiency: Lower efficiency compared to BLDC motors, resulting in shorter flight times.

-

Wear and Tear: Brush wear leads to reduced performance, increased maintenance, and a shorter lifespan.

-

Noise and EMI: Generate electrical noise and electromagnetic interference (EMI), which can disrupt flight control systems.

- Limited Power-to-Weight Ratio: Not ideal for applications requiring high power-to-weight ratios, such as high-speed drones.

-

Efficiency: Lower efficiency compared to BLDC motors, resulting in shorter flight times.

-

UAV Applications:

-

Small, Low-Cost Drones: May still be found in some small, hobby-grade drones where cost is a primary concern and performance requirements are less demanding.

-

Small, Low-Cost Drones: May still be found in some small, hobby-grade drones where cost is a primary concern and performance requirements are less demanding.

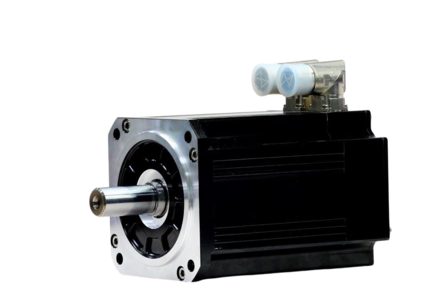

2. Brushless DC Motors (BLDC) in UAVs

-

Dominant Choice: BLDC motors are the most widely used type of motor in modern UAVs due to their numerous advantages:

-

High Efficiency: Significantly more efficient than brushed DC motors, leading to longer flight times and increased range.

-

High Power-to-Weight Ratio: Provide high power output in compact and lightweight packages, crucial for UAV performance.

-

Long Lifespan: Eliminating brush wear significantly extends the lifespan of the motor, reducing maintenance requirements.

-

Quiet Operation: Reduced noise and EMI compared to brushed DC motors.

-

High Efficiency: Significantly more efficient than brushed DC motors, leading to longer flight times and increased range.

-

UAV Applications:

-

Multirotor Drones (Quadcopters, Hexacopter, etc.): Power the propellers for lift and control.

- Fixed-Wing UAVs: Drive propellers for propulsion and control surfaces for flight control.

-

High-Performance Drones: Used in high-speed drones, racing drones, and drones carrying heavy payloads.

-

Multirotor Drones (Quadcopters, Hexacopter, etc.): Power the propellers for lift and control.

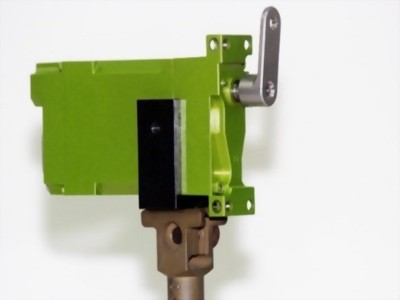

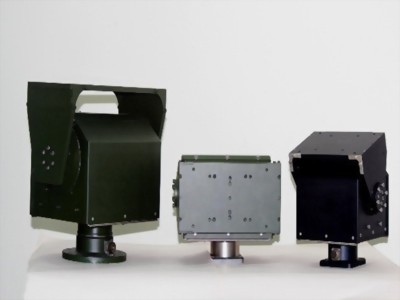

3. Servo Motors in UAVs

-

Precise Control: Servo motors are essential for precise control of various components in UAVs:

-

Flight Control Surfaces: Actuate ailerons, elevators, rudders, and flaps for flight control.

-

Gimbal Stabilization: Control the orientation of cameras and other payloads mounted on gimbals.

- Landing Gear: Control the deployment and retraction of landing gear.

- Other Control Surfaces: Control various other moving parts on the UAV, such as camera mounts and antennas.

-

Flight Control Surfaces: Actuate ailerons, elevators, rudders, and flaps for flight control.

-

Key Features:

-

High Precision: Provide accurate and repeatable positioning, crucial for precise flight control.

- Compact Size: Available in various sizes to suit different applications.

-

High Torque: Provide sufficient torque to actuate control surfaces effectively.

-

High Precision: Provide accurate and repeatable positioning, crucial for precise flight control.

In Summary:

BLDC motors are the workhorses of modern UAVs, powering propulsion and providing efficient and reliable operation.