APPLICATION

What the difference between brushed and brushless DC Motor

What the difference between brushed and brushless DC Motor

The primary difference between brushed and brushless DC motors lies in their commutation methods:

Brushed DC Motors:

-

Commutation: Mechanical.

Brushes and a commutator physically switch the current direction in the rotor coils. - Construction: Rotor has electromagnets, stator has permanent magnets.

- Pros: Simple and inexpensive to manufacture.

-

Cons:

-

Friction and wear from the brushes limit lifespan and efficiency.

-

Generate electrical noise (electromagnetic interference).

- Limited speed due to brush wear.

-

Friction and wear from the brushes limit lifespan and efficiency.

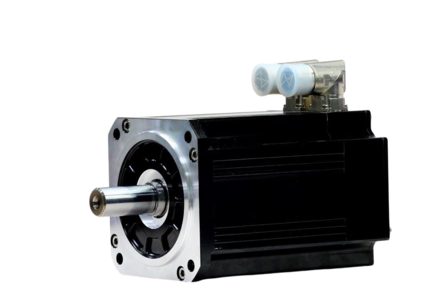

Brushless DC Motors:

-

Commutation: Electronic.

An electronic controller switches the current to the stator coils, creating a rotating magnetic field. -

Construction: Rotor has permanent magnets, stator has electromagnets.

-

Pros:

-

Higher efficiency due to the absence of friction from brushes.

-

Longer lifespan due to no brush wear.

-

Quieter operation with less electrical noise.

-

Higher speeds and greater torque.

-

Higher efficiency due to the absence of friction from brushes.

-

Cons:

- More complex and expensive to manufacture.

-

Require an electronic controller.

In Summary:

Brushless DC motors offer significant advantages in terms of efficiency, lifespan, speed, and noise reduction compared to brushed DC motors.