APPLICATION

How does BLDC motor works

How does BLDC motor works

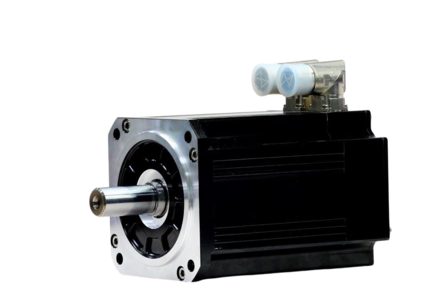

1. Components

- Rotor: The rotating part of the motor, typically containing permanent magnets.

- Stator: The stationary part of the motor, containing electromagnetic coils (windings).

- Electronic Speed Controller (ESC): The "brain" of the motor, responsible for controlling the current flow to the stator windings.

2. Working Principle

- Magnetic Interaction:

- The rotor's permanent magnets create a magnetic field.

- The ESC selectively energizes the stator windings in a specific sequence.

- This creates a rotating magnetic field in the stator.

- The rotor's magnets are attracted to and repelled by the stator's magnetic field, causing the rotor to spin.

- Commutation:

- The ESC constantly monitors the rotor's position (using sensors like Hall Effect sensors).

- Based on the rotor's position, the ESC switches the current to different stator windings.

- This "switching" of current is called commutation.

- Commutation ensures that the rotor is always "chasing" the rotating magnetic field in the stator, maintaining continuous rotation.

3. Key Advantages

- High Efficiency: Reduced friction due to the absence of brushes leads to higher efficiency.

- Long Lifespan: No brush wear and tear extends the motor's lifespan significantly.

- High Speed and Torque: Capable of achieving high speeds and producing high torque.

- Quiet Operation: Smooth and quiet operation due to the absence of brush friction.

In Summary

BLDC motors work by utilizing the interaction between a rotating magnetic field generated by the stator windings and the permanent magnets on the rotor. The electronic speed controller plays a crucial role in controlling the current flow to the stator windings, ensuring efficient and smooth operation.