APPLICATION

Motors and Instruments applications in Robotics

Motors and Instruments applications in Robotics

1. Brushed DC Motors

- How they work: Simple construction with a commutator (rotating switch) and brushes to deliver current to the rotor windings.

- Robotics Applications:

- Mobile Robots, Robotic Arms, Educational Robot, Hobby Robotics

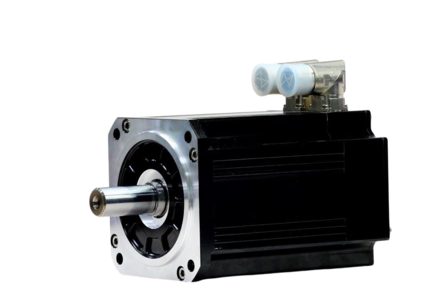

2. Brushless DC Motors (BLDC)

- How they work: No physical brushes; electronic commutation switches current to the stator windings.

- Robotics Applications:

- Widely used:

- High-performance robots: Drones, industrial robots, humanoid robots.

- Advantages: Higher efficiency, longer lifespan, better speed and torque control.

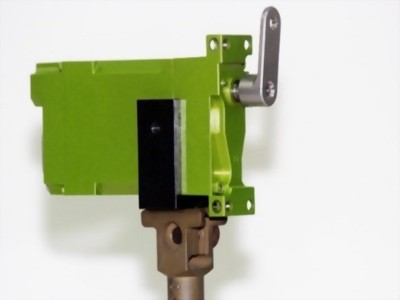

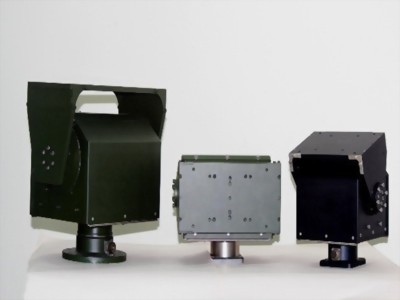

3. Servo Motors

- How they work: A type of motor with built-in position feedback (often an encoder).

- Robotics Applications:

- Precise positioning: Robot arms, grippers, joints in humanoid robots.

- Applications where accurate positioning is crucial: For example, in pick-and-place operations.

In Summary:

- Brushed DC Motors: Suitable for simpler robots, but limitations can hinder performance in more demanding applications.

- BLDC Motors: The preferred choice for many robotic applications due to their superior performance and efficiency.

- Servo Motors: Essential for robots requiring precise and controlled movements.