How does Servo Motor Works

How does Servo Motor Works

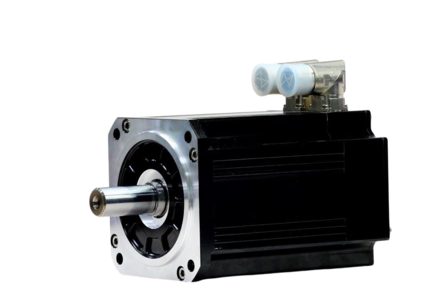

Servo motors are precise actuators that use a feedback mechanism to control their position. They consist of a motor, a potentiometer (position sensor), and control circuitry. When a control signal (usually a PWM signal) is received, the circuitry compares the desired position with the actual position as measured by the potentiometer. Any difference between these positions is used to adjust the motor's speed and direction, ensuring it accurately moves to and maintains the desired position. This feedback loop allows for highly precise control, making servo motors ideal for applications requiring accurate positioning, such as robotics and 3D printing.

Components:

- DC Motor: The heart of the servo, it provides the rotational power.

-

Potentiometer: A variable resistor that acts as a position sensor.

It's connected to the output shaft and provides feedback on the current position of the servo. -

Control Circuitry: This electronic circuitry receives control signals (usually in the form of Pulse Width Modulation - PWM) and compares them to the position feedback from the potentiometer.

-

Gears: These reduce the speed of the motor and increase its torque, allowing for more precise control.

2. Working Principle:

-

Control Signal: A PWM signal is sent to the servo.

The width of the pulses determines the desired position of the servo. -

Position Feedback: The potentiometer continuously measures the actual position of the output shaft.

-

Error Correction: The control circuitry compares the desired position (from the PWM signal) with the actual position (from the potentiometer). If there's a difference (an "error"), the circuitry adjusts the motor's speed and direction to correct the position.

-

Precise Positioning: This feedback loop allows the servo to accurately move to the desired position and maintain it, even if there are external forces trying to move it.

In Summary:

Servo motors work by combining a DC motor with a position feedback mechanism (the potentiometer). This allows for precise control of the motor's rotation, making them suitable for applications that require accurate positioning, such as robotics, RC cars, and 3D printers.

Key Features of Servo Motors:

-

Precision: High accuracy in positioning.

-

Versatility: Can be controlled to rotate to specific angles.

- Compact Size: Available in various sizes to suit different applications.

-

Relatively Simple Control: Can be controlled using PWM signals.