APPLICATION

Difference between Servo Motor and Stepper Motor

Difference between Servo Motor and Stepper Motor

Servo and stepper motors are both types of actuators used for precise motion control, but they have key differences:

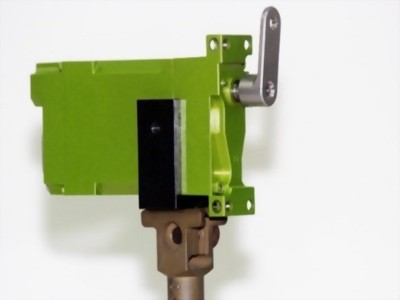

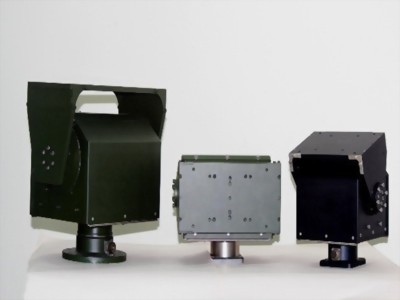

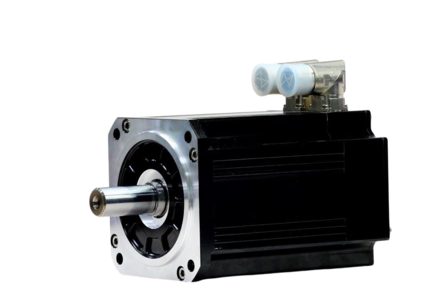

Servo Motors

-

Position Control:

-

High precision in positioning.

-

Use feedback mechanisms (like potentiometers or encoders) to constantly monitor and adjust their position.

-

High precision in positioning.

-

Movement:

- Can rotate to any angle within their range.

- Smooth and continuous rotation.

-

Applications:

-

Robotics, RC cars, 3D printers, industrial automation.

-

Robotics, RC cars, 3D printers, industrial automation.

Stepper Motors

-

Position Control:

-

Move in discrete steps (fixed increments).

-

Typically don't use feedback mechanisms (open-loop control).

-

Move in discrete steps (fixed increments).

-

Movement:

-

Rotate in steps, not continuously.

-

Rotate in steps, not continuously.

-

Applications:

-

3D printers (for some axes), CNC machines, printers, positioning stages.

-

3D printers (for some axes), CNC machines, printers, positioning stages.

Here's a table summarizing the key differences:

In Summary:

-

Choose a servo motor when:

- High precision and accuracy are critical.

- Smooth, continuous motion is required.

- High speeds and high torque are needed.

-

Choose a stepper motor when:

- Precise positioning in steps is sufficient.

- Cost is a major factor.

- Simplicity is preferred.