APPLICATION

Motors and Instrument applications in Aerospace

Motors and Instrument applications in Aerospace

Brushed DC Motors

- How they work:

- Simple construction: A commutator (rotating switch) and brushes deliver current to the rotor windings.

- Magnetic interaction between the rotor and stator fields drives rotation.

- Aerospace Applications:

- Flight Control Surfaces, Landing Gear Actuation, Environmental Control Systems, Fuel System Components, Auxiliary Power Units (APUs)

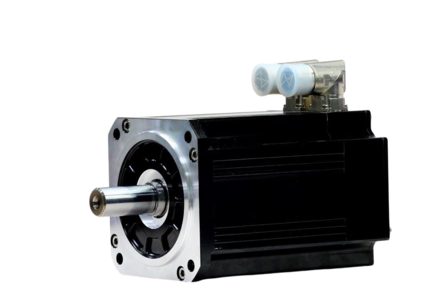

Brushless DC Motors (BLDC)

- How they work:

- No physical brushes; electronic commutation switches current to the stator windings.

- Rotor typically has permanent magnets.

- Offers precise speed and torque control.

- Aerospace Applications:

- Widely used:

- Aircraft: Flight control surfaces (ailerons, elevators, rudders), fuel pumps, landing gear actuation.

- Satellites: Attitude control systems, deployment mechanisms.

- Spacecraft: Reaction wheels, robotic arms.

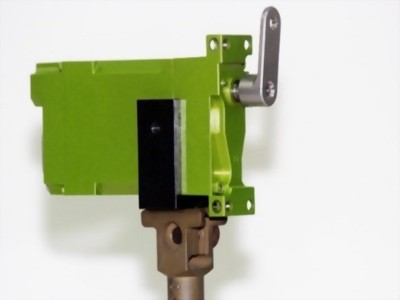

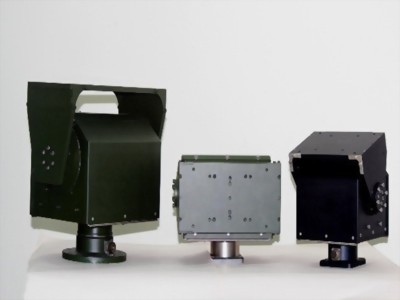

Positioners

- How they work:

- Devices that precisely control the angular or linear position of a mechanical component.

- Often incorporate actuators (like BLDC motors), sensors (like encoders), and control electronics.

- Aerospace Applications:

- Critical for accurate positioning:

- Antenna pointing mechanisms.

- Solar panel orientation systems.

- Robotic manipulators on space stations or rovers.

In Summary:

BLDC motors are the dominant choice in modern aerospace due to their superior performance and reliability. Positioners, often incorporating BLDC motors, are essential for precise control of critical systems. While brushed DC motors have limited applications in aerospace, they may still be used in certain niche cases.