AEROSPACE Electric Motor

Racing Electric Instrument, CO. LTD. has over 20 years of experience working with major clients in the Aerospace industry and achieved AS9100D standard for high quality manufacturing of critical instrument products. As part of high quality assurance and inspection standard, we have the know-how, tools and process in dimension, temperature and stress testing to meet our clients requirements.

Aerospace electric motors are specialized electric motors designed for use in aircraft and spacecraft.

-

Reliability: Extremely high reliability is crucial in aerospace applications where failures can have severe consequences.

-

Weight and Size: Minimizing weight and size is paramount to maximize payload capacity and reduce fuel consumption.

-

Efficiency: High efficiency is essential to minimize power consumption and maximize range and endurance.

-

Temperature Tolerance: Aerospace components must withstand extreme temperature variations.

-

Radiation Hardening: For space applications, components must be resistant to radiation damage.

Key Characteristics:

-

High Power Density: They need to deliver significant power within a compact and lightweight package.

- Rugged Construction: Built to withstand the harsh environments of flight, including vibration, shock, and extreme temperatures.

- Precise Control: Accurate speed and torque control are essential for many aerospace applications.

|

Brushed DC Motor |

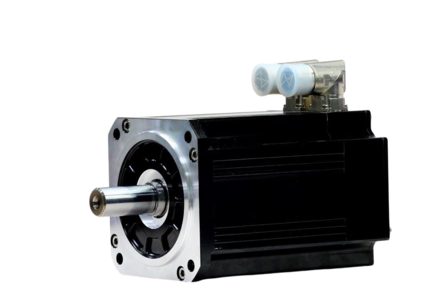

Brushless DC Motor |

|

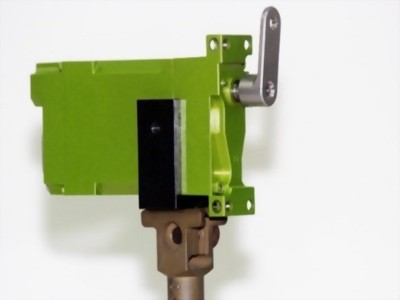

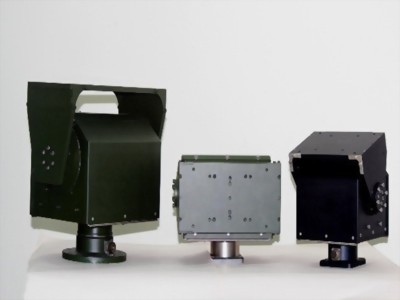

Positioner (Gimbal) |

BLDC |

|

|

|

| No | Subject | Date |

|---|---|---|

| 1 | Aerospace | 2024-12-16 |